Bas relief style CNC milling with an STL

So, we have these pieces that need a certain texture placed on them. Well, less a texture and more a 3D scanned surface of some sort of machine block or something. I’m not entirely sure of the application. All I know is that it requires a very fine surface to be milled so that it matches up with some sort of casting in order to grab it.

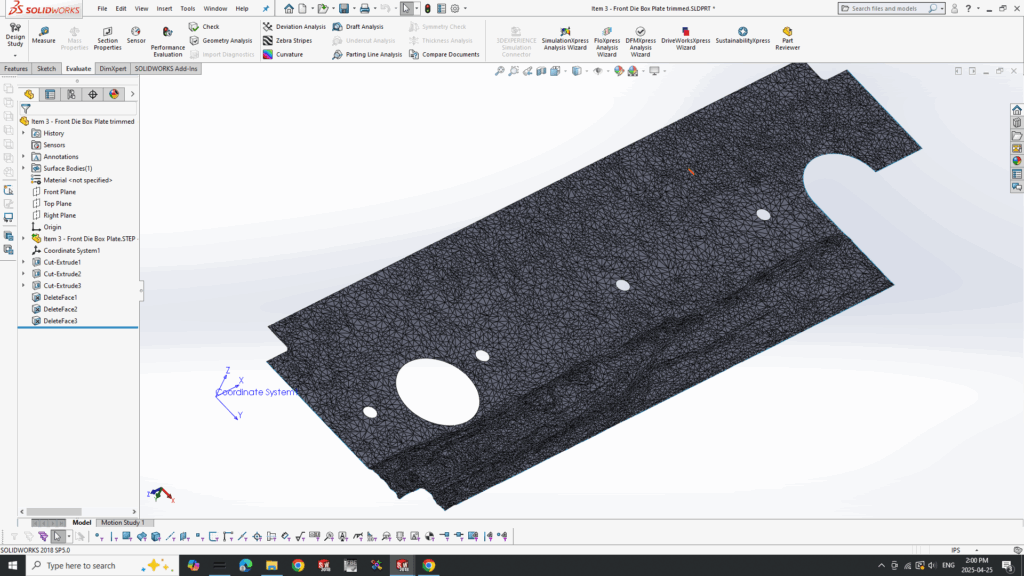

Anyways, were supplied with something like this, some much larger (this one’s 15″x5.5″):

That’s the trimmed up version before I export it. So what I wanted to do was have the surface be milled in a square spiral, basically so that it is always climb milling but that the output is linear, not some weird arc. MasterCAM has a variety of options for surfacing but nothing quite like that. I could have it zig-zag but I didn’t want that.

So, I just programmed my own generator in python. It worked out OK. These are the steps:

- Load the STL file and find its X,Y and Z bounds

- Generate a grid based on the bounds at a resolution of the supplied stepover.

- Add a given number of grid lines to the outside, to give a bit of overlap

- Generate a spiral path with the points

- Scan each point on the grid with the Moller-Trumbore intersection aglorithm, a way to check the intersection of a ray to a triangle in 3D space. Perfect for STL since it’s all triangles.

- Any point that does not have a collision, mark as a non cut

- While scanning, use multiple ray intersections along the ball in order to account for the shape of the ball-nose end mill. (more resolution on the ball==slower)

- Output G-code based on these intersections

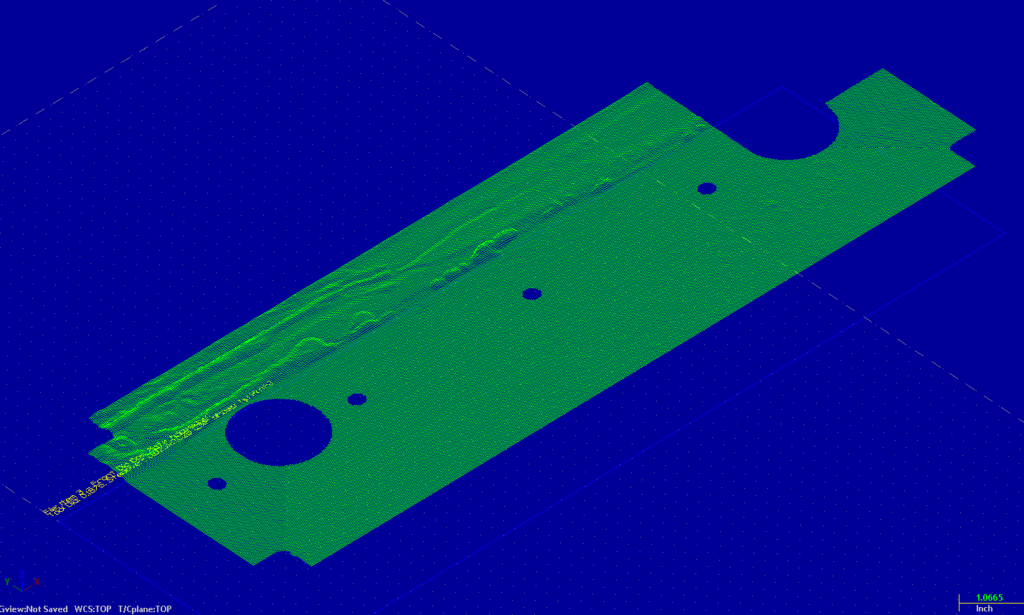

That is the DXF of the output. Works well.

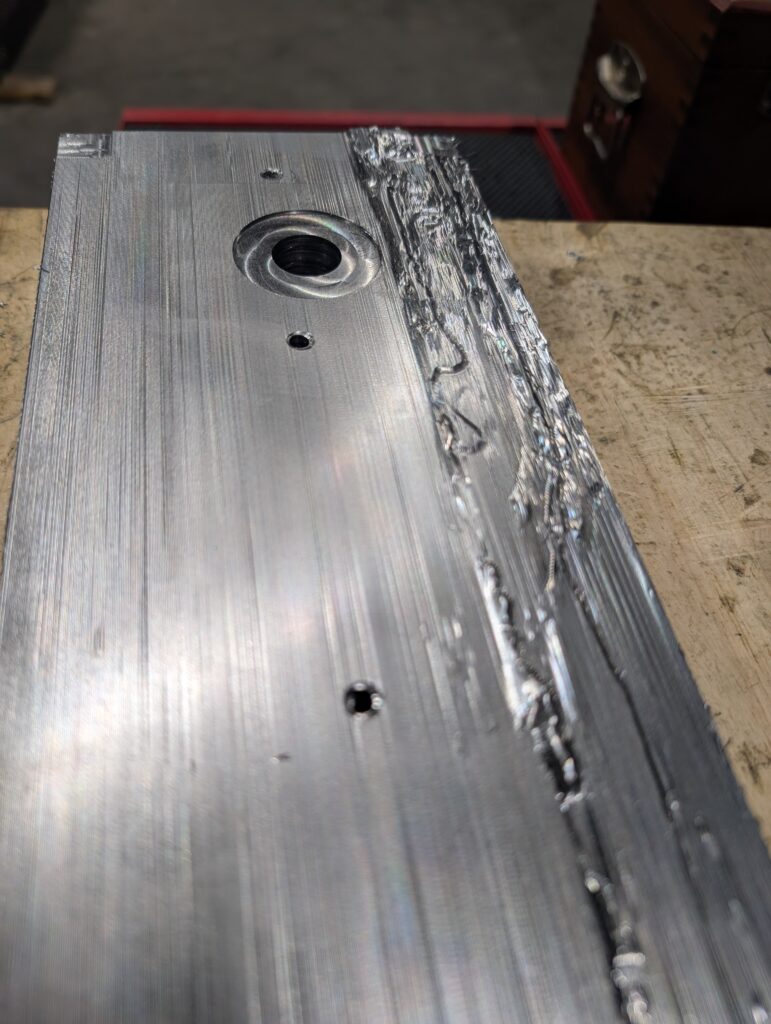

If anyone wants it, they can have it. Enjoy. Also, in case you’re curous to see what it turned out like, here it is. I had to finish it with Mastercam surface routines though but the roughing (done with my program) was pretty good especially after filtering.

Still selling, Comparators!

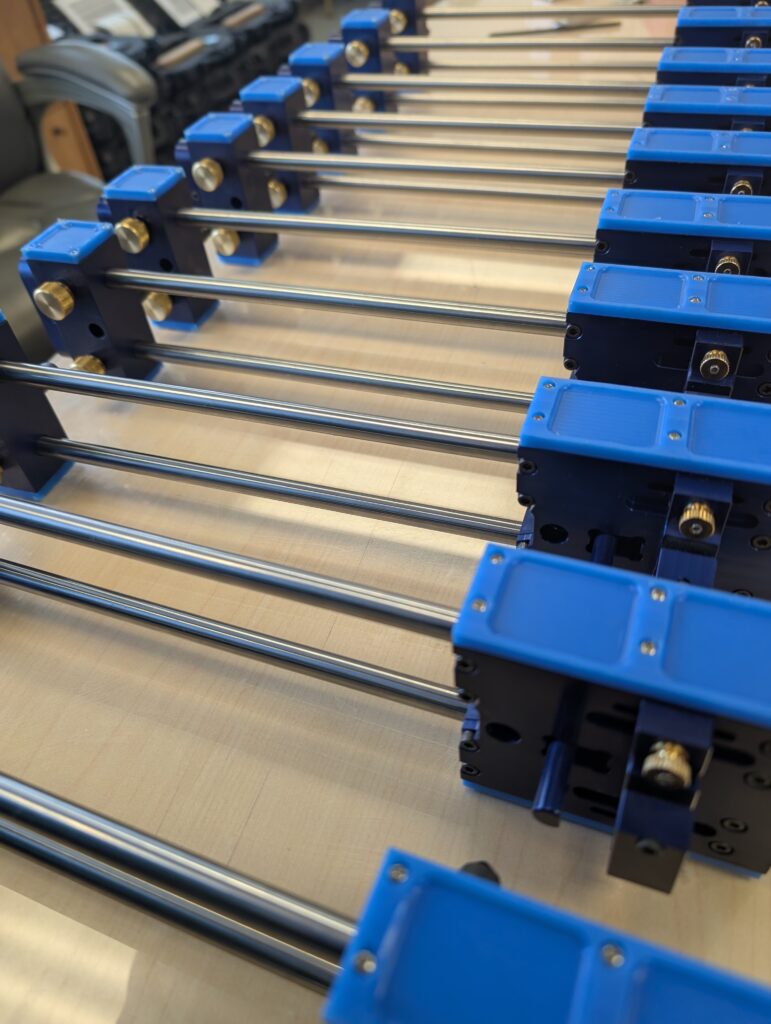

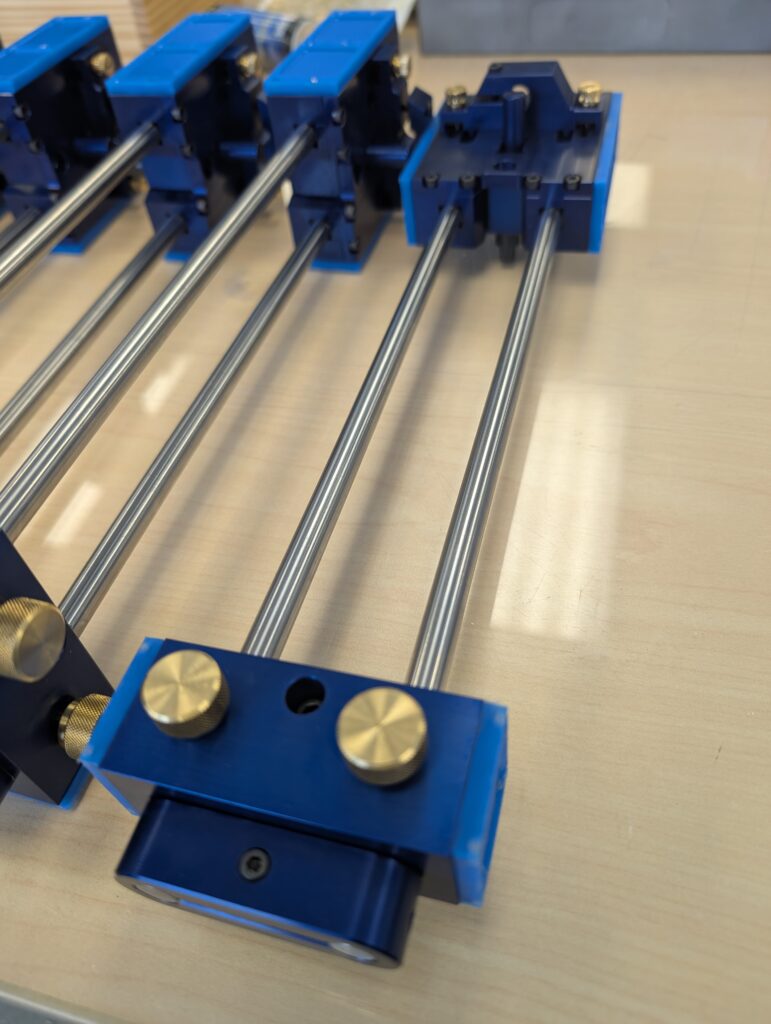

Back in 2018 I designed a type of comparator (and setting master) for compressor valve grooves. Just finished another batch of 10 of them, it went well. Nowadays we wrap the master in paper along with oil in order to prevent rusting. Sending them to the southern states made them rust a fair amount.

Just leaving this here for posterity.

They are a pain in the ass to align well though, I am going to do a mild redesign on the next set. I always say that but we always need them yesterday.

| Posted in Design, Machining | Comments Off on Still selling, Comparators!

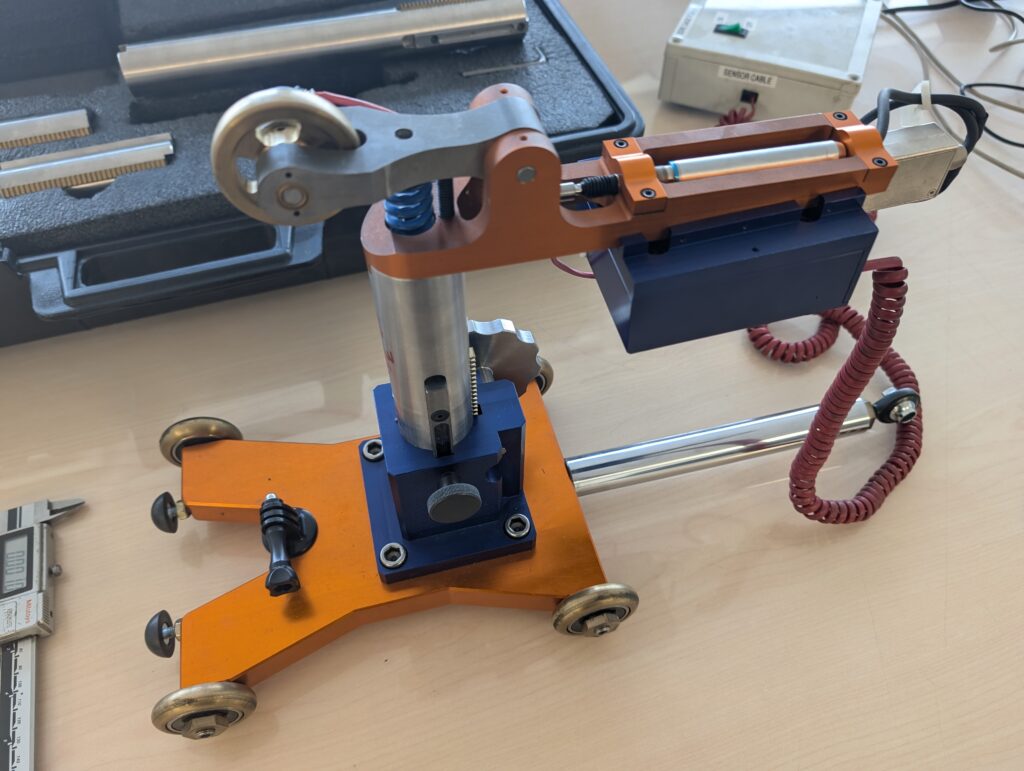

A visit from an old friend, the boreGauge

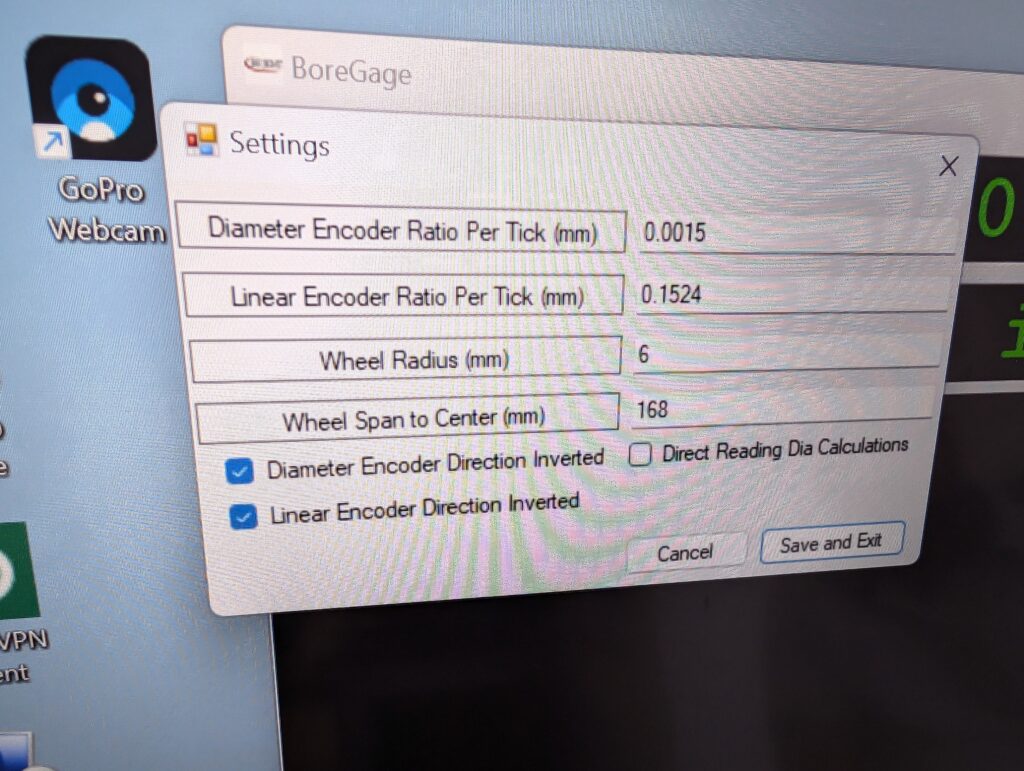

A few years back we made a gauge for measuring large bores in hydraulic cylinders. Seems the company that bought it from us needed the software for it again. I had to dig through my old source code and see if I had a recent version, turns out I did. On this project I did the electronics, software and commissioned it.

What the device does is, you place it in the bore, set your zeros and then measure the bore all the way down. This way you can see if there are any high spots, low spots or waviness. The software keeps track of the position as well and provides a csv file of the data and plots it on the screen.

This was a pretty fun project, I might redesign it and make a more substantial attempt at monetizing it later.

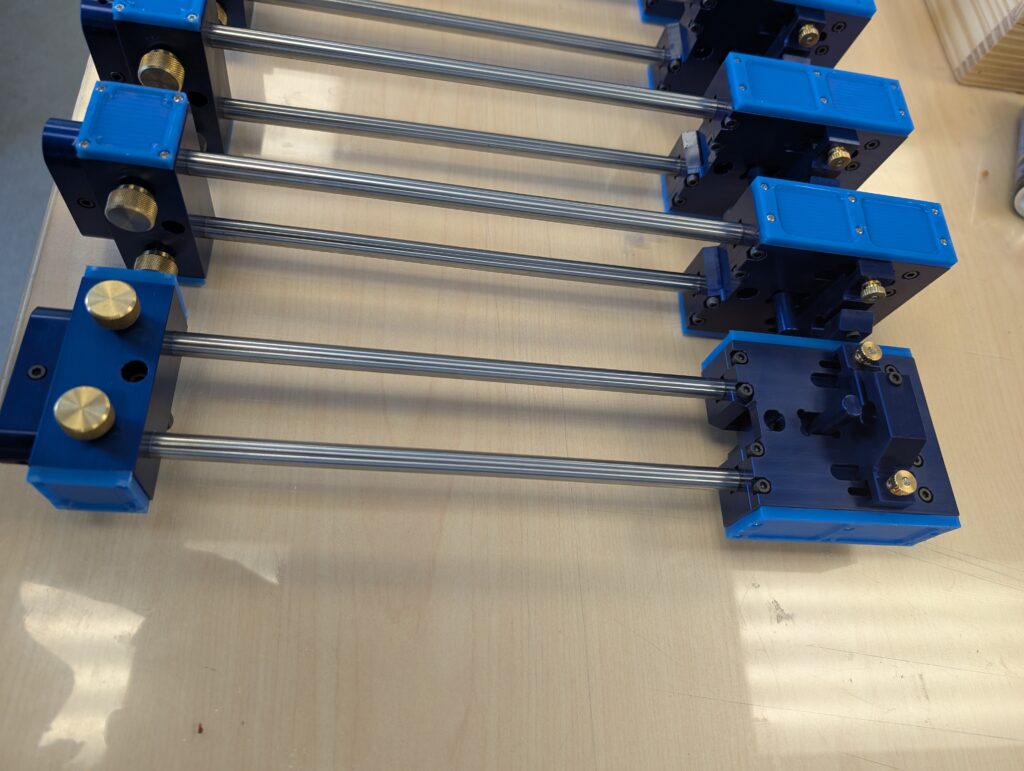

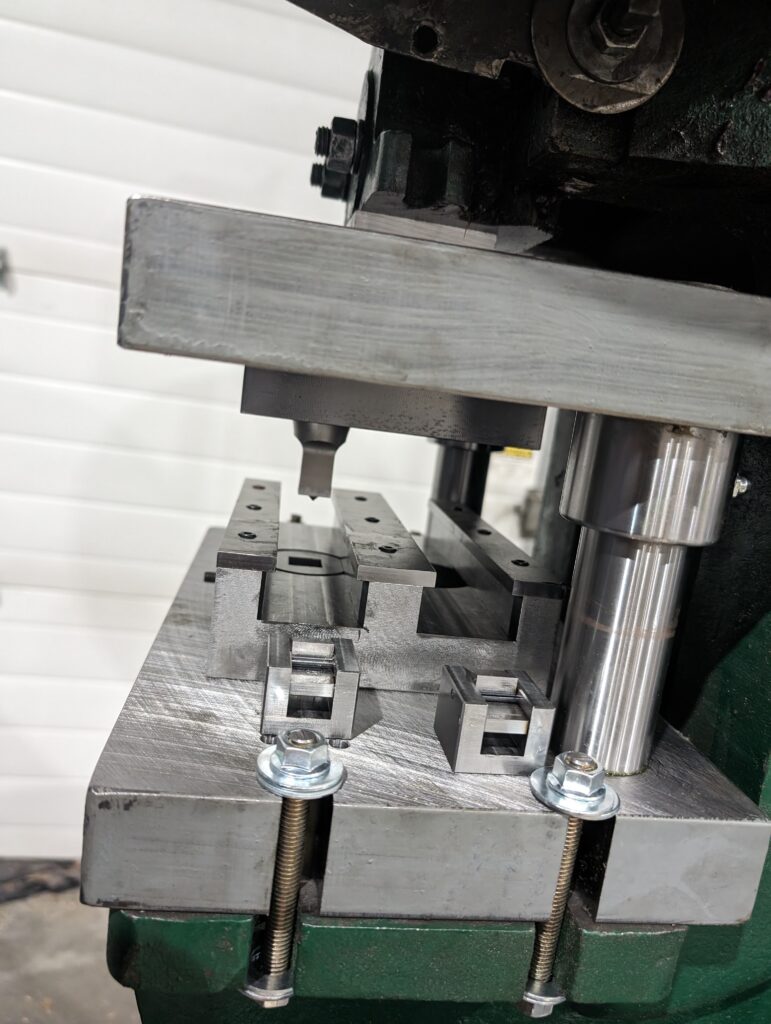

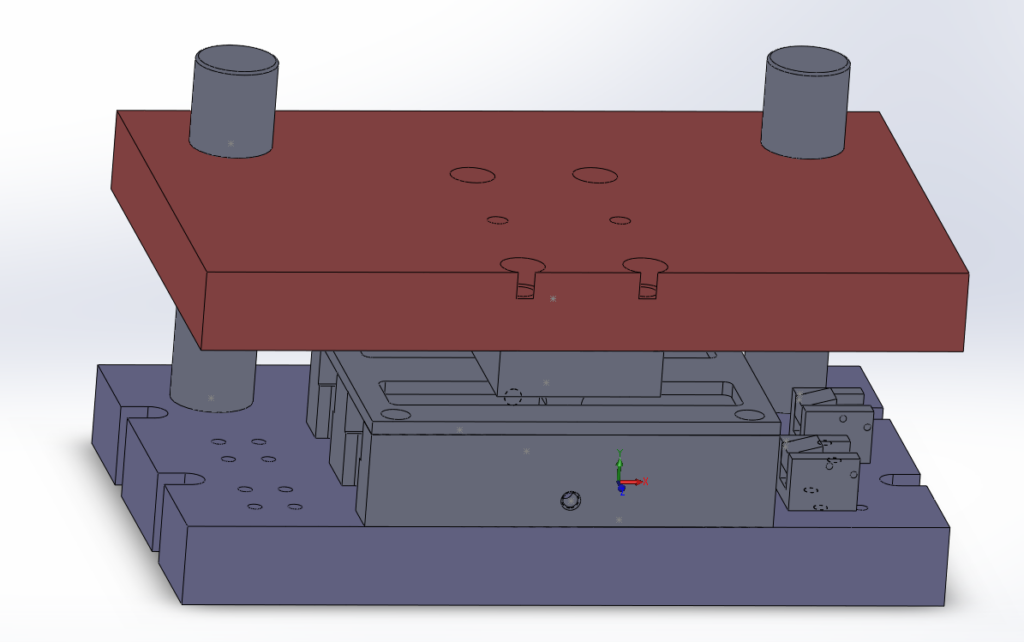

A new die/punch housing

Just finished a new die/punch housing for use on an old press. Works well and allows you to index at different distances. The initial drawing was kind of wrong when I drew it but I just shifted it a bit to work given the machine.

| Posted in Design, Machining, Programming | Comments Off on Bas relief style CNC milling with an STL